Qeb khoom

Zhangjiagang Lub Nroog Zhangyun Machinery Raug Co., Ltd.

Ntxiv: Xindong Road, Daxin Town, Zhangjiagang City, Jiangsu Xeev, Suav

Xov tooj: +86-512-58376558

Fax mus: +86-512-58376989

Ph: +86-13812988858

Tus Thawj Coj Saib Xyuas

Allen Wang:

+86-13812988858

(Xov Tooj / Whatsapp / Wechat)

Email:wangjiabin@zyjxzz.com

Kev Muag Khoom

Lucy Lu:

+86-15601568506

(Xov Tooj / WhatsApp / Wechat)

Email:lucy@zyjxzz.com

Effie Yin:

+86-15370358930

(Xov Tooj / WhatsApp / Wechat)

Email:effie@zyjxzz.com

Emma Geng:

+86-15262329042

(Xov Tooj / WhatsApp / Wechat)

Email:emma@zyjxzz.com

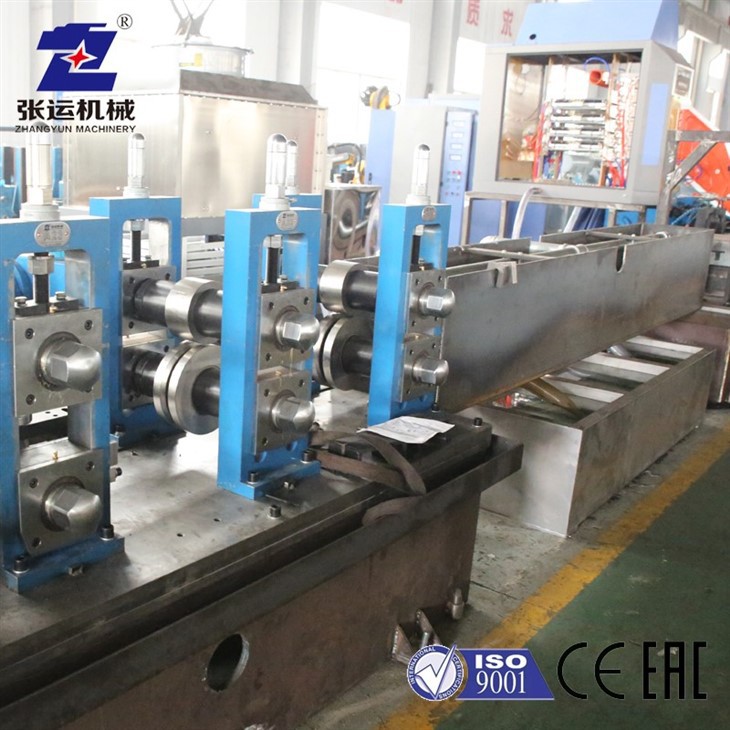

High Frequency Yeeb Nkab Vuam Tshuab

High zaus raj welding tshuab yog ib qho ua tiav cov khoom siv los ua cov kav hlau los yog cov kav hlau ntawm ntau yam xws li square, duab plaub thiab oval. Cov khoom siv raw yog strip steel. Nws cov txheej txheem ua haujlwm raws li hauv qab no: Decoiling steel sawb--- pub cov khoom siv raw--- ua rau hauv ib ncig ntawm cov yeeb nkab --- vuam vuam ntau zaus --- shearing weld caws pliav ---sizing nws mus rau qhov kawg zoo--- txiav.

Tuam txhab Profile

Zhangyun Machinery Manufacturing Co., Ltd. tau tsim muaj nyob rau hauv 2002, peb lub tuam txhab pib cia siab rau cov kev pab zoo hauv zos nyob rau hauv zus tau tej cov khoom siv conveyor.In 2006, Zhangyun Machinery pib tig mus rau cov khoom uas tsis yog-tus qauv R & D, manufacturing thiab muag khoom, uas yog ib tug kws chaw tsim tshuaj paus ntawm txias yob txoj kev. cov cav tov, high-frequency welded yeeb nkab tshuab, of elevator qhia rail ua cov kab ntau lawm thiab tsis-tus qauv tsis siv neeg ntau lawm kab.Qhov kev ua haujlwm siab yob txoj kev tsim los ntawm peb lub tuam txhab tuaj yeem ua cov txheej txheem ntau yam sib txawv. Pab pawg tsim qauv zoo, lub tswv yim ntawm kev sib xyaw ua ke ntawm lub tshuab thiab cov txheej txheem kev tsim cov tshuab ua kom muaj kev ntseeg siab, kev nyab xeeb thiab kev lag luam ntawm cov kab ntau lawm.

tuam txhab kom zoo dua

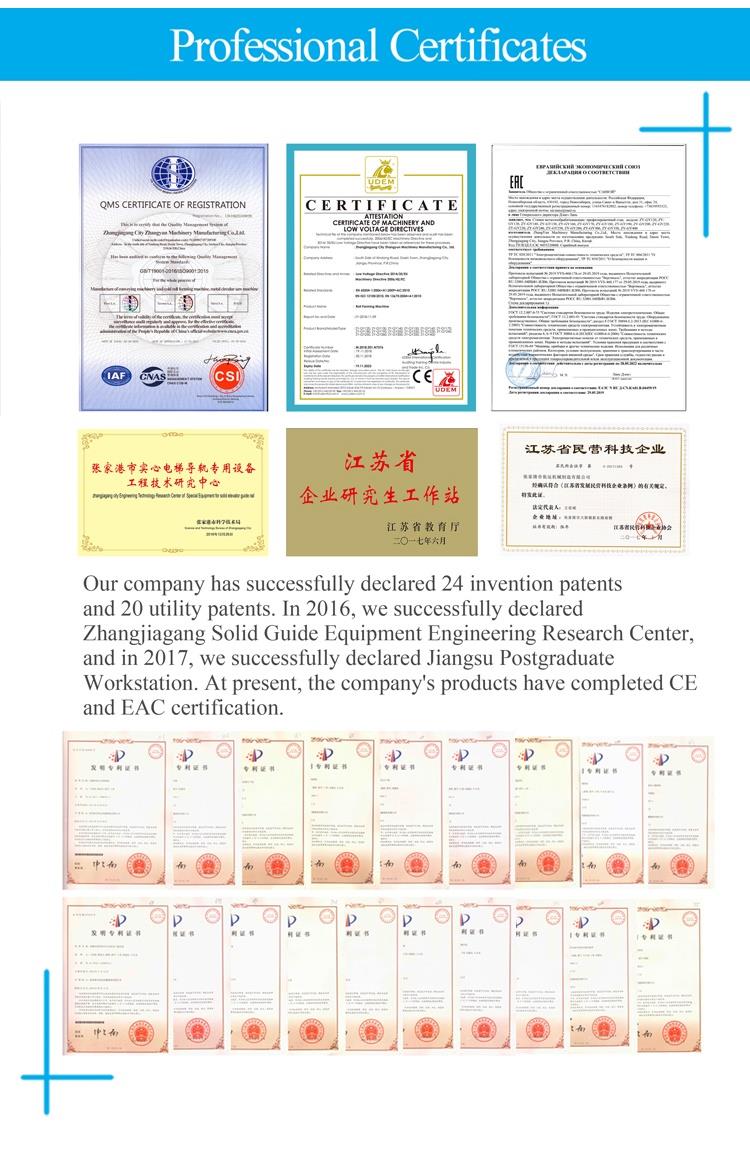

European CE daim ntawv pov thawj

Tag nrho peb cov tshuab tau dhau ISO9001: 2015 Tuam Tshoj Kev Tswj Xyuas Kev Tswj Xyuas Kev Tswj Xyuas Zoo. Thiab feem ntau ntawm lawv tau dhau European CE daim ntawv pov thawj.

Kev tsim khoom lag luam

Peb tau pib ua lag luam thoob ntiaj teb hauv xyoo 2020, thiab tam sim no peb cov khoom tau raug xa tawm mus rau ntau dua 10 lub teb chaws thoob ntiaj teb, suav nrog Tebchaws Meskas, Ltalis, Lub Tebchaws Yelemees, Czech koom pheej, Romania, Nplog, thiab Pakistan. Ntau tus neeg muas zaub tau ua qhov no ntau zaus.

24/7 kev them nyiaj yug online

Yog tias koj muaj teeb meem thaum siv cov khoom, peb yuav teb koj cov kev xav tau sai li sai tau thiab muab kev txhawb nqa loj tshaj rau koj.

Kev tswj kom zoo

Peb muaj cov neeg ua haujlwm tshaj lij los saib xyuas cov txheej txheem tsim khoom, tshuaj xyuas cov khoom thiab xyuas kom meej tias cov khoom kawg ua tau raws li cov qauv tsim nyog, cov txheej txheem thiab cov lus qhia tshwj xeeb.

Φ76 high-frequency tooj liab yeeb welding tshuab yog tsim los tsim welded kav ntawm 30-89 hli inch thiab 1.2-4 0 hli nyob rau hauv phab ntsa thickness raws li zoo raws li square thiab rectangular kav thiab tsim ntu ntawm qhov sib thooj loj.

Stainless Hlau Yeeb Nkab Vuam Tshuab

Cov txheej txheem thev naus laus zis Uncoiling → Shearing → tes welding → Khaws rau hauv accumulator → leveling → Forming → Vuam → Bead Scraper → Txias → Sizing → straighten → Flying saw txiav → Pipe collection

Φ45 high-frequency steel yeeb nkab vuam tshuab yog tsim los tsim welded kav ntawm 12-50.8mm inch thiab 0.6-2.0mm nyob rau hauv phab ntsa thickness thiab square. thiab cov kav dej sib npaug.

High Frequency Yeeb Nkab Vuam Tshuab

Φ50 High Frequency Yeeb Nkab Vuam Tshuab yog tsim los tsim cov kav dej welded ntawm 20-63.5mm inch thiab 0.8-3.0mm nyob rau hauv phab ntsa thickness li square thiab rectangular cev

High zaus raj welding tshuab yog ib qho ua tiav cov khoom siv los ua cov kav hlau los yog cov kav hlau ntawm ntau yam xws li square, duab plaub thiab oval. Cov khoom siv raw yog strip steel. Nws cov txheej txheem ua haujlwm raws li hauv qab no: Decoiling steel sawb--- pub cov khoom siv raw--- ua rau hauv ib ncig ntawm cov yeeb nkab --- vuam vuam ntau zaus --- shearing weld caws pliav ---sizing nws mus rau qhov kawg zoo--- txiav.

Cov txiaj ntsig ntawm High Frequency Yeeb Nkab Vuam Tshuab

High kev nyab xeeb yam

Tsis tas yuav muaj cov pa taws kub hnyiab thiab tawg, uas ua kom muaj kev nyab xeeb ntawm lub neej thiab khoom.

Kev txuag hluav taws xob thiab kev tiv thaiv ib puag ncig

Cov pa phem xws li carbon monoxide thiab carbon dioxide yuav tsis raug tsim thaum lub sij hawm vuam. Piv nrog rau acetylene, roj av, oxygen, liquefied petroleum gass thiab lwm yam gases, tus nqi yog heev txo vim yog siv hluav taws xob.

High efficiency thiab tus nqi qis

Traditional brazing muaj qhov kub tsis tshua muaj vuam, hluav taws xob hluav taws xob loj, cov nqi vuam siab, thiab muaj qhov txaus ntshai ntawm kev tawg. Cov nplaim hluav taws kub ntawm lub tshuab plasma brazing yog tswj tau, qhov vuam kub tuaj yeem ncav cuag ntau tshaj 2000 degrees, thiab qhov ruaj khov yog siab, uas yog ntau tshaj li ob npaug ntawm qhov ceev ntawm acetylene vuam. Nws tuaj yeem welded tsis tu ncua rau kaum ob teev.

Yooj yim nqa

Txij li tag nrho tus tswv tsev hnyav tsuas yog ob peb kilograms thiab me me, nws tsis xav tau acetylene lossis oxygen cylinders, thiab yog qhov tsim nyog rau kev ua haujlwm sab nraum zoov lossis hauv qhov chaw hnyav.

Dab tsi yog Daim Ntawv Thov ntawm High Frequency Yeeb Nkab Vuam Tshuab

Kev tsim kho kev lag luam

High zaus yeeb nkab vuam tshuab tuaj yeem siv los tsim ntau yam khoom siv hauv tsev, xws li cov qauv hlau, kab, kab, thiab lwm yam, thiab yog siv dav hauv kev tsim kho. Nyob rau hauv kev tsim kho kev lag luam, cov khoom siv high-frequency welded yeeb nkab tuaj yeem ua tau sai thiab ua tau zoo tsim cov kav dej welded uas ua tau raws li qhov yuav tsum tau ua, ua rau kev tsim kho kom tiav sai dua.

Kev lag luam roj thiab roj

High zaus yeeb nkab vuam tshuab tuaj yeem siv los tsim cov roj thiab cov kav dej, yog li ua tiav kev thauj mus los ntawm cov roj thiab roj. Cov kav dej welded tsim los ntawm cov khoom siv vuam ntau zaus muaj cov yam ntxwv ntawm lub zog siab, kev tiv thaiv corrosion, thiab kev kub siab tsis kam, uas tuaj yeem thauj cov roj thiab cov pa roj hauv qhov hnyav.

Automotive manufacturing kev lag luam

High zaus yeeb nkab vuam tshuab tuaj yeem siv los tsim cov kav dej welded hauv tsheb chassis thiab lub cev. Cov kav dej welded tsim los ntawm cov khoom siv vuam ntau zaus muaj cov yam ntxwv ntawm lub zog siab thiab lub teeb yuag, uas tuaj yeem txhim kho kev nyab xeeb thiab roj efficiency ntawm lub tsheb.

Kev lag luam aerospace

High zaus yeeb nkab vuam tshuab tuaj yeem siv los tsim cov kav dej welded rau aerospace spacecraft. Kev tsim cov tsheb aerospace muaj cov kev cai nruj rau vuam tshuab. High zaus welded yeeb nkab cov cuab yeej tuaj yeem muab cov kav dej zoo welded, ua rau cov tsheb hauv aerospace ua haujlwm ib txwm nyob hauv ib puag ncig hnyav heev.

Kev lag luam khoom cua txias

Cov yeeb nkab vuam tshuab tuaj yeem siv los tsim cov kav dej hauv cov khoom siv cua txias, xws li cov tshuab cua txias, tub yees, thiab lwm yam. Cov kav dej welded tsim los ntawm cov khoom siv high-frequency welded yeeb nkab muaj cov yam ntxwv ntawm cov cua sov dissipation thiab corrosion kuj, uas tuaj yeem txhim kho. kev khiav hauj lwm efficiency thiab kev pab lub neej ntawm cov khoom cua txias.

Kev lag luam mining

High zaus yeeb nkab vuam tshuab tuaj yeem siv los tsim cov kav hlau txuas hauv cov khoom siv mining, xws li cov hlua conveyor, mining machinery, thiab lwm yam. High zaus welded yeeb nkab cov cuab yeej tuaj yeem muab cov kav dej zoo welded, ua kom muaj kev nyab xeeb thiab kev ntseeg siab ntawm cov khoom siv mining.

Cov txiaj ntsig ntawm High-Frequency Vuam Tshuab yog dab tsi?

Txuag Zog

High-frequency welding tshuab txuag lub zog thaum peb muab piv rau lwm hom vuam. Nws yog eco-friendly vim tias cov pa roj carbon tsawg dua tom qab vuam txheej txheem.Carbon prints yog cov pa roj carbon ntau tso rau hauv huab cua tom qab txheej txheem. Koj tuaj yeem siv txoj kev no thiab txuag lub zog nrog lub zes ntawm cov pob qij txha tsim.

ntseeg tau

High-frequency welding tshuab muaj kev ntseeg siab thiab siv tau. Cov tshuab dyes thiab kev txav ntawm lub bar pab ua kom muaj kev sib koom ua ke zoo tshaj plaws uas tsis muaj dej tsis zoo.

Ua hauj lwm ntawm cov duab sib txawv

Lub tshuab welding high-frequency yog ntau yam hauv nws qhov xwm txheej. Koj tuaj yeem siv cov kev taw qhia meej ntawm lub tshuab los txuas cov pob qij txha tsis muaj zog tshaj plaws.

Siv hauv Waterproofing

Lub tshuab welding high-frequency kuj tseem siv los ua cov npog thiab cov ntxoov ntxoo kom lawv tsis muaj dej. High-frequency welding yog txoj hauv kev zoo tshaj plaws los ua kom cov pob qij txha tsis muaj dej thiab, qee zaum, airtight ib yam nkaus.

Ntau yam khoom siv

Cov txheej txheem no ntawm lub tshuab vuam tshuab siv ntau zaus tuaj yeem siv los khi ntau hom kev sib txuas hauv ntau hom ntaub ntawv. Koj tuaj yeem siv lawv los khi ntau hom ntaub ntawv. Koj tuaj yeem siv lub tshuab vuam ntau zaus rau cov thicknesses sib txawv ntawm cov khoom siv hlau uas koj xav tau.

Rov ua dua

High zaus vuam tshuab muaj ib tug txhim khu kev qha qauv thiab system. Cov txheej txheem vuam hauv cov thev naus laus zis no rov ua dua, thiab yog li ntawd, nws tuaj yeem siv rau hauv kev lag luam.

Txheej ntawm Vuam

Peb tuaj yeem siv lub tshuab vuam ntau zaus rau vuam txheej vim nws muaj cov kauj ruam hauv vuam. Cov khoom muaj ntau txheej ntawm vuam, ua rau lawv muaj zog, roj, thiab dej tsis zoo.

Cheebtsam ntawm High Frequency Yeeb Nkab Vuam Tshuab

High-Frequency Generator

Muaj peb hom tshuab hluav taws xob ntau zaus siv rau kev tsim cov yeeb nkab: lub tshuab hluav taws xob lub cev muaj zog nrog zaus ntawm 10kHz, ib qho khoom siv hluav taws xob hloov hluav taws xob, thiab lub tshuab hluav taws xob hluav taws xob siab zaus oscillator nrog zaus mus txog 100 ~ 500kHz, tom qab ntawd yog qhov siv dav tshaj plaws. Lub zog ntau yam rau cov oscillators siab yog 60 ~ 400kW.

Hluav taws xob

Cov electrode tiv tauj yog ib qho khoom siv tseem ceeb rau kev muab lub zog rau lub raj khoob. Nws yuav tsum ua kom muaj qhov muaj zog tam sim no nyob rau hauv qhov kub thiab txias thiab kev kub ceev zawv zawg kev sib txhuam nrog lub raj phab ntsa. Yog li ntawd, nws yuav tsum muaj siab conductivity, high-temperature zog, hardness, thiab hnav tsis kam.

Induction kauj

Lub induction kauj yog ib qho tseem ceeb ntawm cov high-frequency induction welded yeeb nkab tshuab. Nws cov qauv thiab qhov ntev cuam tshuam rau lub zog hloov dua siab tshiab thiab kev ua haujlwm zoo. Tus qauv induction coil ib txwm, pom hauv daim duab 5-9, feem ntau yog ua los ntawm ib zaug lossis 2 ~ 4 lem ntawm lub nplhaib hlau ua los ntawm cov ntshiab tooj liab square raj, round raj, los yog ntshiab tooj liab phaj, qhwv nrog ib tug insulating iav daim kab xev thiab nrum nrog epoxy resin los xyuas kom meej inter-tig rwb thaiv tsev, nrog rau hauv dej txias.

Cov khoom siv impedance

Cov cuab yeej impedance yog ib qho tseem ceeb ntawm cov cuab yeej pab cuam thaum lub sij hawm vuam ntau zaus. Cov khoom tseem ceeb, cov tub ntxhais sib nqus, ua haujlwm kom nce qhov impedance nyob rau sab nraub qaum ntawm cov yeeb nkab phab ntsa kom txo qhov tsis zoo tam sim no, ua kom cov vuam zoo tam sim no, thiab txhim kho vuam ceev.Cov hlau nplaum yog tsim los ntawm cov khoom siv ferrite (xws li MXO lossis NXO hom) nrog Curie point siab thiab siab sib nqus permeability.

Hom Cov Yeeb Nkab Siab Siab Vuam Tshuab

Xov tooj cua-Frequency (RF) Welders

Xov tooj cua zaus vuam yog ib qho kev xaiv nrov rau kev koom nrog cov ntaub ntawv PVC. RF welders siv electromagnetic nthwv dej los ua kom sov, sib xyaw cov ntaub ntawv ua ke. Cov tshuab no muaj ntau yam thiab muaj peev xwm ua tau ntau yam PVC thicknesses, ua rau lawv zoo tagnrho rau kev siv xws li cov khoom siv hluav taws xob, tsheb sab hauv, thiab cov khoom siv kho mob.

High-Frequency (HF) Embossing Tshuab

HF embossing tshuab yog tsim los tsim cov qauv embossed lossis logos ntawm PVC cov ntaub ntawv. Lawv feem ntau siv rau hauv kev tsim cov khoom zoo nkauj PVC.

High-Frequency (HF) Blister Ntim Tshuab

Hom tshuab no yog siv rau hauv kev lag luam ntim khoom los ntim cov hnab ntim PVC. Nws tsim ib qhov chaw siab ntawm qhov sib khi tuag thiab cov khoom siv PVC, ua kom muaj kev sib khi nruj.

High-Frequency (HF) Vuam thiab txiav tshuab

Cov tshuab no muaj ntau yam thiab tuaj yeem txuas thiab txiav cov ntaub ntawv PVC hauv ib txheej txheem. Lawv feem ntau yog siv los tsim cov hnab PVC, hnab nyiaj, thiab hnab.

Ultrasonic Welders

Ultrasonic vuam tshuab siv high-frequency vibrations los tsim kev sib txhuam thiab kub ntawm PVC Cheebtsam, bonding lawv seamlessly. Cov qauv no zoo meej rau cov ntaub ntawv me me thiab feem ntau siv hauv kev lag luam hluav taws xob rau kev koom nrog cov khoom siv PVC me me.

High-Frequency Induction Welders

High-frequency induction vuam tshuab paub txog lawv cov precision thiab efficiency. Lawv siv electromagnetic induction los ua kom sov hauv cov khoom, ua rau muaj zog thiab ruaj khov welds. Cov tshuab no feem ntau ua haujlwm hauv kev tsim cov kav dej PVC thiab cov raj.

High Frequency Yeeb Nkab Vuam Tshuab Nta

High-frequency yeeb nkab vuam tshuab yog ib yam ntawm high-efficiency thiab lub zog-txuag khoom. Nws siv lub tshuab hluav taws xob ntau zaus induction cua sov, uas tuaj yeem ua kom sov cov kav hlau sai sai thiab ua tiav cov vuam ua haujlwm hauv lub sijhawm luv luv, yog li txhim kho kev ua tau zoo thiab kev ua haujlwm ceev. Nyob rau tib lub sijhawm, siab zaus yeeb nkab vuam tshuab muaj kev siv hluav taws xob siab thiab kev siv hluav taws xob tsawg, uas tuaj yeem txo cov nqi tsim khoom thiab kev siv hluav taws xob zoo.

High zaus yeeb nkab vuam tshuab muaj siab precision vuam nyhuv. Nws siv lub tshuab hluav taws xob ntau zaus induction cua sov, uas tuaj yeem tswj cov vuam kub thiab lub sijhawm, yog li ua kom cov vuam zoo thiab qhov flatness thiab kev zoo nkauj ntawm vuam seam. Ntxiv mus, lub high-frequency yeeb nkab welding tshuab yog nruab nrog high-precision hloov qhov system thiab xyuas qhov system, uas muaj peev xwm saib xyuas thiab kho cov vuam tsis nyob rau hauv lub sij hawm los xyuas kom meej qhov zoo thiab cov nyhuv ntawm vuam.

High-frequency yeeb nkab vuam tshuab yog tsim rau vuam ntau hom hlau kav. Nws tuaj yeem tsis tsuas yog vuam zoo tib yam steel kav, tooj liab kav, txhuas kav, thiab lwm yam, tab sis kuj stainless hlau kav, alloy kav, titanium alloy kav, thiab lwm yam., uas muaj siab hnav tsis kam thiab corrosion kuj. Yog li ntawd, lub siab zaus yeeb nkab vuam tshuab yog dav siv nyob rau hauv ntau lub teb xws li kev tsim kho, kav dej, tsheb, machinery, aerospace, thiab lwm yam.

Kev ua haujlwm ntawm high-frequency yeeb nkab vuam tshuab yog yooj yim heev. Nws txais kev tswj hwm hluav taws xob siab heev thiab tib neeg-tshuab interface, thiab tsuas yog yuav tsum ua raws li cov lus qhia kom ua tiav cov haujlwm vuam. Thaum lub sij hawm ua hauj lwm, lub siab zaus yeeb nkab vuam tshuab yog nruab nrog ntau yam kev tiv thaiv kev nyab xeeb, uas tuaj yeem ua kom muaj kev nyab xeeb ntawm tus neeg teb xov tooj. Ntxiv mus, kev txij nkawm ntawm high-frequency yeeb nkab vuam tshuab kuj yooj yim heev, tsuas yog yuav tsum tau ua kom huv si thiab hloov cov khoom.

Yuav ua li cas xaiv High Frequency Yeeb Nkab Vuam Tshuab

Vuam txheej txheem thiab zoo

Ua ntej tshaj plaws, peb yuav tsum xaiv lub raj xa dej tsis siv neeg vuam tshuab raws li cov teeb meem tseem ceeb hauv cov kav dej vuam uas yuav tsum tau daws ntawm qhov chaw ua haujlwm, raws li cov txheej txheem vuam ntawm kev tsim kho vuam (yog tias koj tsis paub qhov vuam. Cov txheej txheem, koj tuaj yeem tshawb xyuas qhov vuam los ntawm kev sim vuam.Cov nyhuv, vuam efficiency), vuam zoo, vuam efficiency, nqi peev nyiaj thiab lwm yam txiav txim siab uas tsis siv neeg cov yeeb nkab vuam tshuab xaiv, thiab nrhiav kev daws teeb meem uas haum rau koj. Qhov zoo tshaj plaws yog kom hais rau hauv daim ntawv thov.

Cov khoom siv tus nqi

Koj them rau qhov koj them rau. Thaum muas khoom, koj yuav tsum tsis txhob dig muag mus nrhiav tus nqi qis. Koj yuav tsum xaiv cov khoom siv vuam tsis siv neeg uas tsim nyog tshaj plaws raws li kev ua haujlwm ntawm cov khoom siv. Thaum xaiv, koj tuaj yeem mus ncig. Rau vuam tib yam khoom, yog tias tus nqi ntawm cov cuab yeej sib txawv heev, koj tuaj yeem ntsuas nws los ntawm kev sib piv cov khoom siv kho tshuab, lub zog ntawm cov chaw tsim khoom, cov ntsiab lus tom qab muag, thiab kev siv vuam zoo.

Kev tsim nyog tsim nyog

Ua ntej yuav cov khoom siv, cov chaw tsim khoom siv yuav tsum muaj kev nkag siab zoo txog seb nws puas yog kev tshawb fawb ywj pheej thiab kev tsim kho thiab tsim khoom, thiab seb nws puas muaj kev lees paub ntawm kev siv zog. Koj tsis tuaj yeem yuav nrawm raws li cov lus ib leeg. Piv txwv li, qee cov tuam txhab lag luam tuaj yeem nyiag cov duab patents ntawm lwm lub tuam txhab cov khoom lag luam thiab tom qab ntawd tig lawv mus rau hauv lawv cov khoom tseem ceeb. Qhov tseeb, cov khoom siv tsis muaj cov ntsiab lus technical thiab tsis muaj kev txhawb nqa kev ntseeg siab.

Khoom thiab kev pabcuam zoo

Kev pabcuam lav yog qhov tseem ceeb hauv kev yuav khoom. Kev ruaj ntseg zoo, kev cob qhia txuj ci, kev soj ntsuam kev pabcuam, thiab lwm yam yog txhua yam tseem ceeb hauv kev txiav txim siab seb yuav yuav khoom. Raws li lub hauv paus ntawm kev lees paub ib xyoos, Tianjin Yixin muab kev cob qhia pub dawb rau ntawm qhov chaw, kev soj ntsuam kev pabcuam ua tiav, thiab txuas ncaj qha rau cov neeg ua haujlwm cov nyiaj hli nrog kev pabcuam zoo, thiab tau cog lus los muab kev pabcuam vuam tshuab ua tiav.

★ Thawj weld, ces daim ntawv. uas yog, thawj weld rau hauv ib puag ncig raj, ces mus rau hauv ib tug tshwj xeeb-zoo li tus tube.Xws li lub raj raj, oval, dow tubsteel caw, thiab lwm yam.Qhov zoo ntawm cov qauv no yog tias nyob rau hauv zus tau tej cov ntau hom steel hlab, thaum uniform. sawb qhov ntau thiab tsawg tau tso cai, tsuas yog ib txheej ntawm cov chais yuav tsum tau welding lub voj voog thiab tom qab ntawd cov seem sib txawv tau txais ntawm ib txoj kab uas hla.

★ Ua ntej sib sau, ces welding.Cov yeeb nkab nrog cov seem profile tsis tuaj yeem tau txais los ntawm kev deformation ntawm cov yeeb nkab, yog li cov molding ncaj qha thiab vuam yog xav tau.Qhov zoo ntawm kev sib sau ncaj qha yog qhov zoo ntawm cov khoom tsis txwv ntev li ntev tau. Tus naj npawb ntawm cov thav duab ua tau raws li qhov yuav tsum tau ua ntawm deformation passage.Nws qhov tsis zoo yog qhov loj ntawm yob ua.

Yuav Ua Li Cas Thiaj Ua Tau Siab Ntau Cov Yeeb Nkab Vuam Tshuab

♂ Khaws lub taub hau vuam, tuag thaiv thiab ua haujlwm huv;

♂ Tshawb xyuas seb cov hlua txuas puas xoob tsis tu ncua, thiab ceev nws lub sijhawm yog tias nws xoob;

♂ So cov khoom siv tsis tu ncua tab sis tsis txhob so nrog kua. Tsis txhob nias lossis tso kua dej rau saum lub chassis tseem ceeb rau kev co;

♂ Ua kom huab cua ntshiab hauv chaw ua haujlwm. ambient kub yuav tsum tsis txhob siab dhau. Cua txias tuaj yeem siv los ua kom txias;

♂ Roj lub lifting grooves thiab screws tsis tu ncua thiab ua kom lawv huv si thiab lubricated;

♂ Thaum koj tuav lub tshuab PVC vuam rau muag, lub thawv vibration yuav tsum tau muab cais tawm ntawm lub tshuab lub cev tuav;

♂Thaum cov cuab yeej siv tsis siv sijhawm ntev, so lub ntsej muag ntawm lub tshuab, thiab roj rau kev tu. Muab lub foob rau nws thiab muab tso rau hauv qhov chaw qhuav qhov cua;

♂Yog tias muaj qhov tawg ntawm lub taub hau vuam ntawm HF vuam tshuab, thov hloov nws lub sijhawm kom tsis txhob muaj kev puas tsuaj rau qhov chaw ntawm lub chassis tseem ceeb;

♂Thaum ua haujlwm, lub rooj vibration yuav tsum tsis pub dhau thaj tsam liab. Yog hais tias nws qhia tias yuav dhau ntawm thaj tsam liab, txo cov naj npawb ntawm cov khoom tso tawm kom thiaj li txo tau qhov siab;

♂ Muaj cov kab hluav taws xob siab nyob rau hauv lub ntsiab txee ntawm kev co generator ntawm HF vuam tshuab. Tsis yog cov kws tshaj lij tsis raug tso cai los kho hauv tshuab;

♂ Cov kab hauv av ntawm cov khoom siv yuav tsum tau grounded. Nws tsis tuaj yeem txuas nrog cov khoom siv hluav taws xob kom tsis txhob muaj hluav taws xob ntau.

Peb Cov Khoom

Zhangyun Machinery Manufacturing Co., Ltd. tau tsim muaj nyob rau hauv 2002, peb lub tuam txhab pib cia siab rau cov kev pab zoo hauv zos nyob rau hauv zus tau tej cov khoom siv conveyor.In 2006, Zhangyun Machinery pib tig mus rau cov khoom uas tsis yog-tus qauv R & D, manufacturing thiab muag khoom, uas yog ib tug kws chaw tsim tshuaj paus ntawm txias yob txoj kev. cov cav tov, high-frequency welded yeeb nkab tshuab, of elevator qhia rail ua cov kab ntau lawm thiab tsis-tus qauv tsis siv neeg ntau lawm kab.Qhov kev ua haujlwm siab yob txoj kev tsim los ntawm peb lub tuam txhab tuaj yeem ua cov txheej txheem ntau yam sib txawv. Pab pawg tsim qauv zoo, lub tswv yim ntawm kev sib xyaw ua ke ntawm lub tshuab thiab cov txheej txheem kev tsim cov tshuab ua kom muaj kev ntseeg siab, kev nyab xeeb thiab kev lag luam ntawm cov kab ntau lawm.

Daim ntawv pov thawj

FAQ

Cim npe nrov: high zaus yeeb nkab vuam tshuab, Tuam Tshoj, lwm tus neeg, manufacturers, tsis siv neeg, zoo tshaj plaws